Optimized Local Surface Treatment

OLST technology (Optimized Local Surface Treatment) is a plating of copper on aluminium. The two metals are inseparably welded together in a special process based on dynamic gaz cold spray associated to a fast moving robot.

This process combines the advantages of light metals – low weight, easy workability, etc. – with the advantages of copper, such as corrosion resistance, the property of being soldered, special features for electrical purposes.

Main characteristics of the OLST technology:

- Good adherence

- Clean and precise process without any conductor deterioration

- Minimal oxidization

- High thermal and electrical conductivity

- Stable phase and basic material composition

- High density, low porosity, dense coating

- Ability to combine materials normally incompatible (electrolytic action)

- Wide range of coating materials

Key applications:

- Low inductive Laminated Busbars

- Power Connection Rails

- Heat sink, CTE mismatch, better solderability

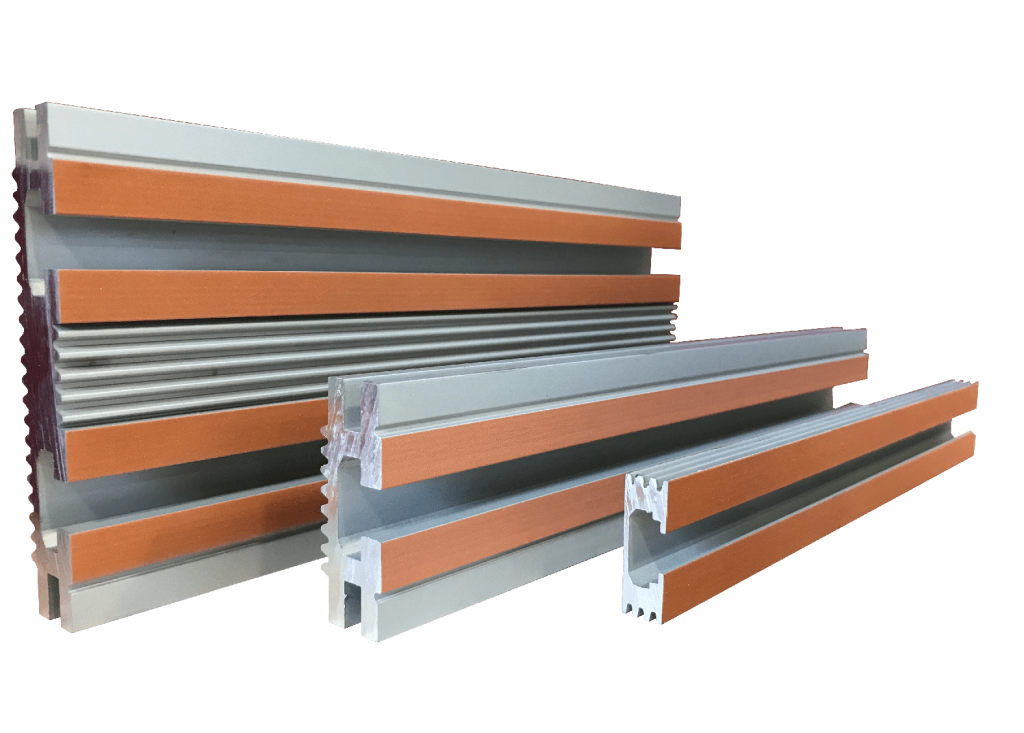

Power Connection Rails: Universal & innovative aluminium profiles

- An economical alternative to your copper busbars up to 1600A

- Copper-plated contact surface for an excellent connection quality

- Weight savings: up to 58% compared to copper bars

- Compatible with a large range of holders

- Easy and quick assembly / wiring

- No need to drill holes, no limited number of connections

- Easy to add connections after installation